Our expertise

Filament winding

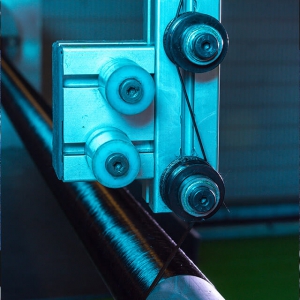

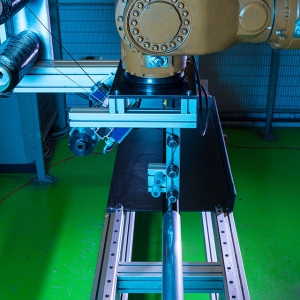

Filament winding is an automated process that consists of laying up a back and forth system of pre-preg composite material threads on a mould or mandrel. Depending on the setting of the movement speed with respect to the rotation speed you can obtain a circumferential or helicoidal winding.

The advantage of this process is that it allows you to make very rigid composite parts with excellent compression resistance. CPL has two filament winding machines: max. diameter: 1000 mm, max. length: 2500 mm (but with the possibility of making longer tubes by sleeving/bonding).